WO2017072736(既出)

(実施例要素は複数、最初にat least oneで後が楽)

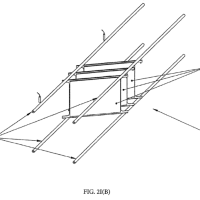

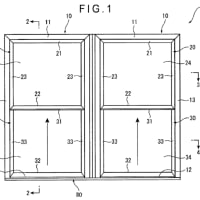

The supporting frames 2, 3 preferably have a tubular shape, for example obtained by coupling two half-shells having a C or L section. Advantageously, the supporting frames 2, 3 are made of extruded materials, such as extruded aluminum or, alternatively, reinforced extruded plastic materials. The conveying system 100 further comprises at least one plurality of driving elements 12 supported by the two supporting frames 2, 3 and at least one motor 9 for driving at least one portion of said plurality of driving elements. Preferably, the motor 9 is a DC motor 9. Preferably, for each supporting frame 2, 3 there are a plurality of driving elements 12 extending side by side, substantially along the whole extent of the conveying system 100.

In the embodiment shown in figure 1, the driving elements 12 comprise at least one plurality of wheels rotatably constrained to the supporting frames 2, 3 by means of supporting shafts 12a.

In particular, the conveying system 100 includes at least one transmission assembly to transfer the motion from the motor 9 to at least one plurality of driving elements 12. In detail, each supporting shaft 12a is rotatably constrained to the supporting frame 2 or 3 by means of at least one bearing. The supporting shafts are driven by drive belts or chains (not shown in figures), preferably housed inside the frames 2, 3, which constitute the transmission assembly to transfer the motion from the motor 9 to the wheels 12, that is to say to transfer the motion of the drive shaft to at least one supporting shaft 12a.

In particular, in the embodiment of figure 1, the drive shaft of the motor 9 is fitted inside the supporting frame 3 and the motor 9 is constrained to the supporting frame 3 from the outside. In further embodiments the motor 9 can be entirely housed inside the supporting frame 2 or 3, though still falling within the protection scope of the present invention.

Further embodiments can provide for driving elements 12 different from the wheels shown in figure 1, such as roller, belts, etc., though still falling within the protection scope of the present invention. By driving the wheels 12, or in general the driving means 12, it is possible to displace for example goods or products along the feed direction F of the conveyor 100.

The conveying system 100 is provided with a control system to control the driving of the driving elements 12. Preferably, the control system comprises at least one control unit 11 housed, for example, inside the supporting frames 2, 3, and at least one sensor (not shown) for detecting bodies that is arranged along the feed path of the conveyor 100. In particular, the control unit 11 operates one or more motors 9 depending on the signal received from the sensors for detecting bodies, in order to ensure that the goods or products smoothly circulate along the feed direction.

For example, the control system can drive one or more motors 9 for driving the driving elements 12 associated with a path portion in which an object to be fed is detected. In other words, if no product to be fed is detected in a path portion, the driving elements 12 are not driven until an object, for example approaching and coming from a path portion upstream of the feed direction F, is detected.

The control system can be, for example, of the master-slave type, i.e. provided with master control units and slave control units. The control system is located in one of the two supporting frames 2,3.

Preferably, the slave control units are connected to each other and, in turn, each of them is connected to a master control unit through an AS-interface data exchange cable allowing to exchange information and coordinate the slave control units. Therefore, said at least one AS-interface data exchange cable mainly runs inside one of the two supporting frames 2,3.

Therefore, the conveying system 100 can be split into macro working areas each defined by a master control unit and multiple slave control units, each of the latter being associated with a motor 9(*既出だが不定冠詞;敢えての不定冠詞;each motorでも良いと思う)and with at least one sensor for detecting bodies. The master control unit processes the command to be submitted to the slave control units depending on the signal coming from the sensor for detecting bodies of each secondary zone. Preferably, each secondary zone is individually controlled, so that the fed goods or products can not ever touch one another. The driving elements 12 of a zone are not driven until the subsequent zone (i.e. downstream along the feed direction F) is empty.

The conveying system 100 is further provided with a power supply system to electrically supply the control system and the motor 9. In particular, the power supply system comprises at least one power supply board 7 designed to convert the mains voltage.

※コメント投稿者のブログIDはブログ作成者のみに通知されます