US7495363

"BACKGROUND OF THE INVENTION

DC motors are known in the art. Various control system implementations in a variety of architectures typically depend on a DC motor as the prime motive force. For example, a DC motor may serve to rotate or translate a panel, structure, or related device.

Designers continually face the challenge of packaging and power density with respect to DC motors. Designers typically must strive to put as much power for as low cost in as small volume as possible. In almost every control system product, a cost Pareto analysis will reveal that the most costly single component is the motor, just as it is the prime constraint to achieving a certain level of performance. In the past twenty years, motor drive electronics have been reduced dramatically in terms of size and price to enable unprecedented capability for a given package size. However, there have been no significant improvements in DC motor technologies. Many current actuation systems face an immediate need(*必要)for small, high power, low cost motors, and face with price targets that present day technologies may not meet.

For example, brushless DC (BLDC) motors require more touch labor(*手作業)to produce as they become smaller. This is primarily because of the difficulty of winding many turns of fine wire in the slots of the stator. The best winding fill that can be produced goes towards 50% or less as the slots become smaller. Also, the motor constant (torque/root-watt) gets smaller and smaller, becoming unacceptable at some point. The performance in actuation systems also suffers as the motor gets smaller because of the reduction in bandwidth resulting from the relationship of torque diminishing faster than inertia. Thus, for the smallest actuation systems, the BLDC motors become too expensive, too sluggish, or both.

As a result, in the realm of small actuation systems, brush motors have become the motor of choice. This has been primarily on the basis of motor rotor diameter versus motor overall diameter. The performance is better than equal size BLDC motors, but frequently is not good enough. The smallest brush motors are likewise very expensive for the same reasons, and also suffer from brush noise and lack of reliability. The brushes and commutator bars pose potential problems during long storage and over-demanding environments.

In view of the aforementioned shortcomings associated with motor design for small actuation systems, there is a strong need(*必要)in the art for a motor suitable for use in small actuation systems without sacrificing cost and/or performance. Moreover, there is a strong need in the art for a method of making such a motor.

...

DETAILED DESCRIPTION OF THE INVENTION

The present invention is a motor which is suitable for use in small actuation systems without sacrificing cost and/or performance, as will become more apparent based on the following detailed description. Generally speaking, the present invention is a motor, and preferably a multi-phase brushless DC motor, produced with a small number stator windings within each slot. In a preferred embodiment, there is only a single turn winding within a given slot. As will be appreciated, the single turn stator windings allow the conductor (e.g., copper) fill of the stator slots to be maximized. The resulting motor is operated by what may be viewed as an exceptionally low voltage, high current inverter.

The motor of the present invention offers many advantages over conventional designs. For example, the maximized fill of the stator slots allows for a reduction in stator cross section, thus allowing for a larger rotor diameter for a given overall diameter. Moreover, the interconnection of the single turn or few turn windings can be performed by automated processes such as wire bonding as used in the hybrid electronics industry as discussed below.

The low voltage, high current inverter (servo-amplifier) drives the motor and operates preferably in a different voltage/current regime than the inverters used with conventional motors. Specifically, the present invention incorporates an inverter which utilizes high current power switches, such as those recently developed for use in desktop computing as is explained in more detail below.

The motor of the present invention will now be described with reference to the drawings, wherein like reference labels are used to refer to like elements throughout.

Referring initially to FIG. 1, a, maximum conductor motor 10 and inverter 12 are shown in accordance with an exemplary embodiment of the invention. In the exemplary embodiment, the motor 10 is a three-phase brushless DC motor, although it will be appreciated that the motor 10 could instead include some other number of phases without necessarily departing from the scope of the invention(*発明の範囲). Also, the motor 10 may include brushes and/or be an AC motor without necessarily departing from the scope of the invention.

The inverter 12 includes a controller 14 and a switching network 16. The switching network 16 includes a DC source such as a voltage/current supply 18together with a plurality of switches SW1 thru SW6. The voltage/current supply 18 and switches SW1-SW6 are configured to provide three-phase power (Phases A, B and C) to the motor 10 as will be readily understood by those having ordinary skill in the art. The windings of the motor 10 may be connected in a delta or wye configuration, for example.

The controller 14 is configured as is conventional(*従来、慣用、通常)to provide switching control signals to the switches SW1-SW6 such that the switches are turned on/off(*オンオフ)at appropriate times(*タイミング)to apply three-phase power voltages to the motor 10. In the exemplary embodiment, the motor 10 includes one or more rotor position sensors (not shown) such as a Hall effect device or the like(*等), which provide position feedback signal(s) to the controller 14. Based on such feedback signal(s), the controller 14 turns on/off the switches SW1-SW6 in known fashion(*公知)in order to apply the appropriate phase voltages from the voltage/current supply 18 to the motor 10.

As will be explained in further detail below in connection with FIGS. 2-6, the motor 10 includes a stator having slots which, unlike conventional motors, preferably includes only a single turn(*巻き数)of any given phase winding. By making the winding in each slot a single turn, the motor 10 may be manufactured without labor intensive hand winding, etc. In the smallest motors 10, such approach is believed to enable levels of performance not currently possible with conventional motor design. Even if each slot 10 includes a small number of turns, e.g., 10 or less, the present invention still provides advantage in reduced fabor, etc.

In the preferred embodiment, since each slot in the motor stator includes only a single turn winding of a given phase, the resulting torque constant, back emf, inductance and resistance of the motor 10 will be very low as will be discussed herein. Consequently, the switching network 16 of the inverter 12 must be capable of high current, low voltage electronic switching. The present invention draws from recent developments in the desktop computer market. Specifically, power switches have been developed that can handle the high currents and rapid switching called for by the motor 10. For example, the switches SW1-SW6may be any of a variety of commercially available power switches such as DirectFET™ power MOSFETs from International Rectifier, or similar devices from Vishay Company. Such switches make the high current, low voltage switching of the inverter 12 both feasible and inexpensive.

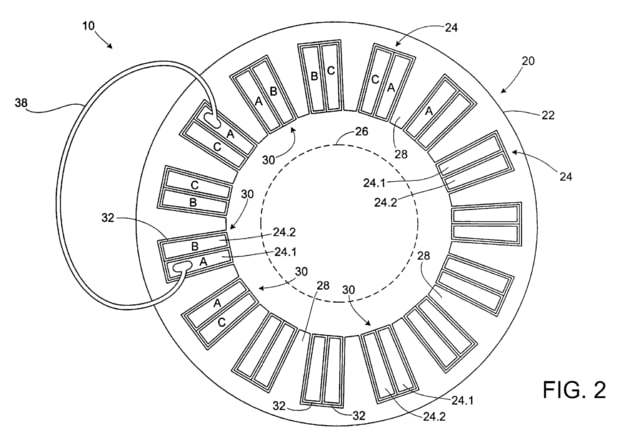

Referring now to FIG. 2, the motor 10 is shown in relevant part in accordance with an embodiment of the present invention. The motor 10 includes a stator assembly 20 made up of(*から成る)a stator 22 and windings (generally designated(*参照番号)24). In addition, the motor 10 includes a rotor 26 shown in phantom(*透視線、仮想線、破線). The rotor 26 is of conventional construction. Thus, further detail as to the rotor 26 has been omitted for sake of brevity(*省略).

The stator 22 is conventional in that(*通常、従来通り)it includes a plurality of teeth 28 and a plurality of slots 30 defined between respectively adjacent teeth 28. The stator 22 is further conventional in that it may be made up of a stack of laminations(*積層), etc. In another embodiment, as discussed below, for example, the stator 22 may be a conventional slotless stator. The particular makeup(*構成)of the stator 22 itself also is not germane to the invention, and thus further detail has been omitted for sake of brevity.

In the exemplary embodiment, each slot 30 includes two copper bars 24.1 and 24.2, respectively. The copper bars 24.1 and 24.2 are positioned side-by-side(*並列)within the slot 30 and each represent an electrical conductor. Although the bars 24.1 and 24.2 are preferably copper in the exemplary embodiment, other electrically conductive materials may be used without departing from the scope of the invention.

The copper bars 24.1 and 24.2 represent winding segments and run the length of(*端から端まで、長さに亘って)the respective slot 30. Moreover, the copper bars 24.1 and 24.2 are sized such that when positioned side-by-side in the respective slot 30, the copper bars 24.1 and 24.2 fill substantially all of the cross-section of the slot 30 (i.e., in the plane shown in FIG. 2). The copper bars 24.1 and 24.2 each include an electrically insulating sheath 32 which serves to insulate the copper bars from one another while minimizing the non-electrically conducting fill within the cross-section of each slot 30. The sheath 32 may be made of(*で形成、成る)a layer of varnish, rubber, high-temperature plastic, etc., as will be appreciated.

In accordance with the invention, the copper bars 24.1 and 24.2 in each of the slots 30 are interconnected in a predetermined manner at their respective ends. More specifically, the respective ends of the copper bars 24.1 and 24.2 are exposed at the top and bottom of the stator stack 22. The copper bars 24.1 and 24.2 are interconnected with each other such that each copper bar represents a single turn belonging to one of the windings (i.e., the A-phase winding, the B-phase winding or the C-phase winding). The manner in which the windings of the different phases are distributed throughout the slots 30 is conventional in accordance with multi-phase motor winding techniques. The present invention is not intended to be limited(*非限定)to any particular distribution pattern of the different phases as will be appreciated. The present invention is different from conventional winding techniques in the sense that instead of many turns for a given winding being present in a slot, each copper bar within a slot 30 forms only a single turn for a respective winding.

Thus, for example, FIG. 2 illustrates how a given slot 30 includes copper bars 24.1 and 24.2 designated as being a single turn for the A-phase winding and the B-phase winding, respectively. Although shown in FIG. 2 only for two turns each belonging to the A-phase winding, respective turns for the respective windings are electrically connected by an interconnect 38. Each interconnect 38 may be, for example, a wire(*電線、ワイヤ)which is wire bonded to the copper bars 24.1 and 24.2 at respective ends using conventional wire bonding techniques as shown more clearly in FIG. 3. Alternatively, for example, each interconnect 38 may be a conductive bar soldered or welded at respective ends to the copper bars 24.1and 24.2 as shown in FIG. 4.

As will be appreciated by those having ordinary skill in the art, other techniques may be used for forming each interconnect without departing from the intended scope of the invention. For example, the interconnects 38 may be formed using electrodeposition, electrical connectors, soldering, welding, cold forming, stereolithography, etc. The present invention is not necessarily limited to a particular manner for forming the interconnects 38 unless otherwise specified.

Referring to FIG. 5, the interconnects 38 may be used to form the appropriate phase winding interconnections between the copper bar ends on both the top and bottom of the stator assembly 20. In addition, or in the alternative, the copper bars 24.1 and 24.2 may be formed and bent as represented(*示す)in FIG. 6 in order to form a pair of connected turns. For example, the copper bar 24.2 in FIG. 6 is shaped in somewhat of a U-shape(*U形). The sides of the U are inserted into corresponding slots 30 to represent a single turn of a given winding within the slots. The base of the U forms an electrical interconnect between the turns.

FIG. 6A shows another embodiment analogous to the embodiment of FIG. 5, with the exception that(*例外、以外、除いて)the interconnects 38 are formed by particular wiring patterns included in/on a printed wiring board (PWB). The ends of the copper bars 24.1 and 24.2 can be mounted to the respective wiring pattern in/on the PWB(s) using conventional surface mounting techniques, as will be appreciated.

For ease of illustration, it will be appreciated that the drawings herein show only but a few of the interconnections between the turns. However, even with all of the appropriate connections between the copper bars 24.1 and 24.2 for the respective phases, it will be appreciated that the labor associated with making such connections is much less than that required for forming conventional multi-turn windings, particularly with smaller sized motors.

Although the above embodiments have been described primarily in the context of there being only a single turn of a winding in a given slot, it will be appreciated that a larger number of windings could be utilized in a given slot. However, it will be necessary to then provide additional interconnects 38 to interconnect the multiple windings as will be appreciated. Thus, the present invention is preferably limited to a smaller number of turns (i.e., ten or less), within a given slot.

FIG. 7 is a flowchart representing a method for making the stator assembly 20according to an embodiment of FIGS. 1 and 2 of the present invention. In step S50, the stator 22 is formed of a lamination stack with teeth 28 and slots 30. The stator 22 may be formed using conventional stator forming techniques, and thus further detail, is omitted.

In step S52, the winding segments (e.g., copper bars 24.1 and 24.2) for the slots 30 are formed. In one embodiment, the segments are extruded using an electrically conductive material and cut to length. The insulating sheath 32 can be formed separately or as part of the extrusion process. In another embodiment, the segments may be cast in the appropriate shape and length. Although extrusion or casting represent preferred manners for forming the segments, any method may be used without departing from the scope of the invention."

※コメント投稿者のブログIDはブログ作成者のみに通知されます