Brazing, Wikipedia

"Brazing is a metal-joining process in which two or more metal items are joined(接合)together by melting and flowing(流す)a filler metal(ろう)into the joint(接合部), the filler metal having a lower melting point than the adjoining metal."

Brazing Process Fundamentals

ろう、ろう材:filler metal

How Brazing Works

ろう:brazing filler metal

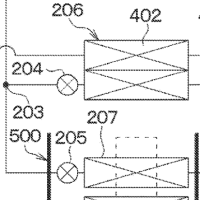

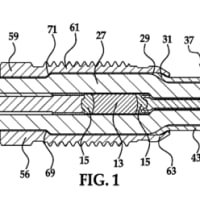

WO2006110329(特表2008-536122)

"5. The microwave level gauge of Claim 1 wherein braze joints(ろう接合部)between the upper and lower support bands and the ceramic seal body have a shrink fit(収縮適合)that provides radial compression to the ceramic seal body."

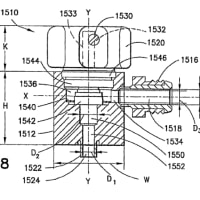

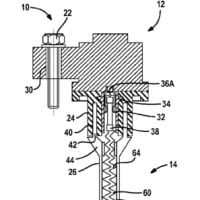

WO2006017231(特表2008-505731)

"18. A method according to claim 15, further comprising prior to hermetically sealing(密閉的に密封)the substrate edge, placing a relatively high temperature brazing alloy(ろう接合金)on an upper portion of an electrically insulative member and outer surface of the insulator to the ferrule sealingly surrounding(密封状態に取り囲む)an intermediate portion(*複数要素の単数記載)of the conductive elements abutting(当接)a like plurality of(同様の複数の;*conductive elementsと同様の複数の)discrete ferrule bores and feedthrough pins; and applying heat to melt the brazing alloy."

"FIG. 2 is a graphical representation of the empirical dimensional data of FIGS. IA, IB, and 1C wherein the height straightness(直線度)16, width straightness 18, and capacitor cavity (edge) straightness 20 dimensions (and standard deviations for each) as set forth(示す;*記載)in the table of FIG. IA for the exemplary eight-hole ferrule 100. While the ferrule 100 depicted in FIG. IB and FIG. 1C has a series of bores 102, greater or fewer such bores 102 may populate(存在する)the ferrule 100. In addition while the ferrule 100 is depicted as an elongated member having a linear array of bores 102, both the ferrule 100 and the bores 102 can be shaped into any convenient configuration, such as a geometric and/or irregular shape."

"Surrounding the pins 104,108 at their junction with apertures formed in the ferrule 100 an electrically insulative material 114 ensures that the pins 104,108 are hermetically sealed to the ferrule 100 to prevent ingress of body fluid or debris into the interior of the associated IMD. The insulative material 114 can comprise any known insulator or potting compound or the like, including: a polysilicon material, a glass material, an amorphous material, a ceramic material. In addition, a layer of relatively high temperature brazing alloy 115 is deposited on top of the insulative material 114 as additional barrier to ingress of body fluid and the like in to the IMD. Note that a brazing material also joins the insulator material 114 to the ferrule at the "black squares" located along side each insulator presented in FIG. 3C such that 360[deg.] of each insulator is hermetically joined to ferrule member (100) by the braze material."

WO2005070601(特表2007-518575)

(Ab)

"In order to avoid excessive internal stress and micro structure problems inherent with previous fusion welding techniques utilised for component structure fabrication, the present method creates a relatively thin in situ brazing alloy(ろう接合金)layer upon first and second component edges which are brought together in order to create a component joint. This in situ brazing alloy layer (6, 23, 26) is created by deposition of brazing elements, such as copper or nickel, from an electrical discharge cutting process electrode depletion utilised in order to cut the component edges. A subsequent brazing technique then creates through interstitial migration between that brazing alloy layer and the underlying material substrate of the components a robust(強固)component joint(構成要素継手;*部品接合部). Furthermore, the in situ brazing alloy layer penetrates the respective component cut edge surface to only a limited depth such that the geometric effect is similarly limited, and the properties of the underlying component material structure are maintained."

WO2014045287(特表2015-531687)

"It will be appreciated that when two metallic parts are joined(接合)by brazing(ろう付け)in one or in several areas, only the surface areas of metal that are to be brazed are coated by the brazing filler. After the brazing operation, the filler is disposed between these parts. Only a small share of filler goes out of the joined parts(接合部品). It has been found that in a given corrosion environment, different corrosion potential values between the joint and the base metal small surface area of the external joint do not exert a noticeable galvanic effect on the base metal. However, at the same time, the base metal exerts a strong galvanic effect on the brazing joint which has a small surface area with respect to the surface area of the base metal component. Consequently, when the joint has a more negative corrosion potential than the base metal, it may undergo intensive corrosion attack, but when the joint potential has a higher potential than the base metal, particularly, when a metal of platinum group is added to the brazing filler, the brazed joint has been found to be more corrosion resistant and does not influence the corrosion stability of the base metal."

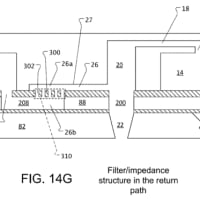

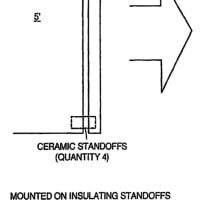

US20060164785(特表2006-517341)

(Ab)

"The invention concerns an electrostatic chuck (250) comprising an upper ceramic (205) bearing the substrate (200) to be treated and a lower ceramic (215) bearing heating elements (225) and radio frequency electrodes (220), said ceramics being permanently bonded together. Said ceramics are preferably bonded together by heated glass and the lower ceramic is fixedly assembled to a pedestal, for example through a soldered bonding(ろう接合)."

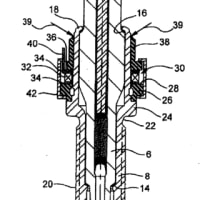

WO2015153180(特表2017-511565)

"The lead wire 1114 may be a Nisil lead wire, which may be coupled through ABA gold brazing(ろう付け)to the outer surface near a connection end of the heating element 808. In some embodiments, the lead wire 1114 may be attached using the landing pad 1000, or the end of the lead wire 1114 may be flattened prior to attachment, as described above.

[0052] As shown in FIG. 7E, the ABA gold braze(ABA金ろう) connects at least one of a metal sealing ring 1100 to a ceramic heating element 808 of the glow plug, the metal sealing ring to a housing 812 of a fuel cell system, a center lead wire 1112 (e.g., Nisil alloy wire) to a hollow inner portion of the ceramic heating element 808, and/or a coiled lead wire 1114 (e.g., Nisil alloy wire) to an outer portion of the ceramic heating element 808.

[0053] An advantage of using ABA gold braze is that a ceramic material may be bonded to metal without having to first metalize the ceramic. By utilizing ABA gold braze rather than AgCu28 + Ti2 paste at braze junctions(ろう接合部), erosion of the heating element 808 at temperatures greater than about 779 degrees C may be prevented. Furthermore, ABA gold braze allows a single braze material(ろう材料)to be used during glow plug assembly. Use of ABA gold braze further may reduce the number of braze cycles(ろう付けサイクル), for example, from 3 to 1."

最新の画像[もっと見る]

-

流入出口

4日前

流入出口

4日前

-

弁室

1週間前

弁室

1週間前

-

わたって重なる

2週間前

わたって重なる

2週間前

-

絶縁碍子

2週間前

絶縁碍子

2週間前

-

絶縁碍子

2週間前

絶縁碍子

2週間前

-

絶縁碍子

2週間前

絶縁碍子

2週間前

-

絶縁碍子

2週間前

絶縁碍子

2週間前

-

CDプレーヤー修理:ア~ムカミン!

2週間前

CDプレーヤー修理:ア~ムカミン!

2週間前

-

CDプレーヤー修理:ア~ムカミン!

2週間前

CDプレーヤー修理:ア~ムカミン!

2週間前

-

CDプレーヤー修理:ア~ムカミン!

2週間前

CDプレーヤー修理:ア~ムカミン!

2週間前