In the process of manufacturing complex molds, the application of five-axis machining is more and more extensive. Now many of them are 5 Axis machining products. Using five-axis machining can reduce the number of tooling and machine tools required for machining parts. The number of devices will be minimized, which means that the total processing time is also reduced. CNC functions are getting stronger and stronger, which also allows CNC manufacturers to offer more five-axis features.

For those who have never used five-axis machining, these feature applications make five-axis machining very simple, and CNC technology is used on five-axis machining, so that five-axis machining has the following advantages:

Reduce the need for special tools so that the tool offset can be set after the part program is allowed. In general, the design of the general program is supported, so that the post-processed program can be used interchangeably between different machine tools;

It can improve the quality of finishing; it can be used on machine tools with different structures, so that it is not necessary to explain the spindle in the program or the workpiece is rotating around the center point. Because it can be solved with CNC parameters. The other five-axis CNC applications are also characterized by the ability to rotate the tool around the spindle, the characteristics associated with rotating the part around the spindle, and the ability to allow the operator to manually change the number of tools.

Fully automated Thermoforming Machines are packaged in roll film forming, so film is required to pull the associated conveyor. At the time of work, the base film needs to be preheated and then the sealing and pulling process is received during the sealing and cutting process. Generally, the power is from the conveying chain arranged on the longitudinal sides of the machine. Each section of the chain is fitted with a clip that automatically clamps the base film from start to finish. The transfer chain can feed the base film from the beginning of the machine to the terminal in a continuous step. The general standard chain is driven by a two-speed three-phase motor. The feed is usually driven at a high speed, so that it can be automatically switched to a low speed before stopping at each step, and each step can be stopped accurately. End position.

Because of the stepper motor drive, electronic control can be achieved without speed regulation. This type of drive allows the chain to run at a uniform rate during the initial phase of each feed, allowing for a step-down in the termination phase. This type of driving prevents the package from spilling out of the tray when the circular object and liquid are wrapped, because the chain is quickly started or stopped quickly.

DPXB/40B Advanced Thermoforming Packaging Machines

Many old drivers know that there will be a series of problems after using the car for a while. For example, the noise is getting bigger, the car is shaking hard, and the fuel consumption is getting bigger. This is actually a serious consequence of the wear caused by the car engine.

It is said that the engine is the heart of the car, and there is no routine maintenance of the engine, which is very important for car maintenance. How can we really manage the use of the engine reasonably? The old driver tells you the correct way to maintain the car Honda GX160 engine.

The first is the engine oil, because the Honda GX160 engine is very important to use the oil. Usually, the gasoline engine is based on the attachment and use conditions of the exhaust pipe system, so that it can select a suitable oil for the engine. The standard should generally not be lower than the manufacturer's specified value. When the outdoor ambient temperature is lower, our engine oil can be selected to have a small viscosity, and vice versa.

Many well-known brands of lubricating oil have good anti-wear performance, and the oil with good anti-wear performance can reduce the wear of the engine, so it can prolong the life of the engine. Moreover, it can effectively suppress the generation of carbon deposits and sludge, thereby reducing the wear of impurities in the oil passage on the engine surface. While regularly cleaning the engine water tank to remove rust and scale, it is also necessary to periodically clean the fuel system to control carbon deposits and maintain the best condition of the engine.

It is important that the car engine needs to rely on the water tank to cool down, otherwise the engine will burn out easily and cause fatal damage to the engine. It is usually necessary to ensure that the coolant in the tank is kept at a normal level. To choose a good quality, especially in winter, you should also select the appropriate coolant according to the ambient temperature. In the normal maintenance of the car, the engine antifreeze needs to be replaced every year.

In some cold weather conditions, the engine should be preheated before driving. Only when the engine is at normal temperature can the running resistance, wear and function between the parts reach the best state, so that it will not be right. The engine caused damage.

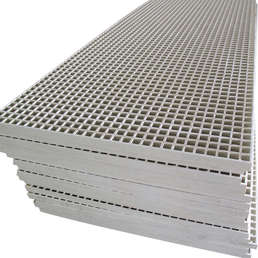

Fiberglass sheets are a new type of environmentally friendly composite material that is widely used in the construction industry, so it is quite common in people's daily lives.

Fiberglass Panel is also called fiberglass board, fiberglass insulation board and fiberglass composite board. Because these are made of glass fiber material and high heat resistance composite material, it is safe and environmentally friendly, and contains no asbestos harmful to human body. .

Glass fiberboard is generally used to make the soft base layer, and then cloth and leather and other materials are used to make beautiful wall and ceiling decoration. So it may exist everywhere in daily life, but many people don't understand it, so they don't find it.

1. The specific advantages of Fiberglass Panel are sound insulation, heat insulation, flame retardant and environmental protection. Moreover, it also has high mechanical properties and dielectric properties, and has good heat resistance and moisture resistance, so it has good processability. Fiberglass panels can be used in plastic molds, injection molds, mechanical manufacturing, molding machines, drilling machines, injection molding machines, motors, PCBs, ICT fixtures, and countertop polishing pads.

Injection mold molding is usually required for high temperature materials and low temperature molds. In the same machine condition, it is necessary to use the heat insulation method. While keeping the mold injection low temperature, the temperature of the injection molding machine cannot be too high. In this case, it is only necessary to install an insulating and insulating plate between the injection molding and the injection molding machine. It can shorten production time, increase productivity, reduce energy consumption, and improve the quality of finished products. Continuous production process ensures stable product quality and prevents machine overheating.

2. The plywood with glass rod dimension adhered to the surface of the fiberglass board is manufactured under high temperature and high pressure, and its outer surface has high quality moisture resistance.

Such panels are suitable for use in the manufacture of containers. Available in sizes up to 3,658 mm, the board can be any size up to 12 meters. The glass fiber content is 25-40% by weight. The standard colors are gray and sub-white.

3. The main raw materials are low-alkali cement and alkali-resistant glass fiber, which are easy to produce and easy to obtain non-metallic materials, with less production process requirements and environmental protection.

Human resource outsourcing is very common in today's society. Many large companies have handed over the internal personnel affairs of the company to professional labor companies. The benefits are obvious. However, when choosing to do Human resource outsourcing, there are some aspects that need to be paid attention to. When choosing to do Human resource outsourcing, enterprises should pay attention to the following four points:

1. Functional selective outsourcing, many of which are human resources basic affairs work, which can be outsourced. Many companies will outsource talent recruitment, and now the outsourcing of file management, attendance records, payroll and compensation and benefits is now showing a rapid growth trend. However, if it involves corporate culture, employee relations and performance appraisal, and this is related to the core competitiveness of the company, it cannot be easily outsourced.

2. To choose the appropriate outsourcing service organization and determine what functions can be outsourced, it is necessary to choose an outsourcing service organization. Outsourcing services determine the quality of management in the future. For SMEs, this is a matter of life and death. Enterprises must pay attention to the service quality and service reputation of outsourcing service organizations. This requires consideration of the price of the service, and then the credibility and quality of the service organization, which plays a decisive role in the completion of the outsourcing work and the normal development of the entire enterprise.

3. The high-level attaches importance to the communication of the outsourcing process. Therefore, enterprise personnel outsourcing does not mean that all the affairs are outsourced. It is the first priority to choose which functions to outsource. Then, by understanding the outsourcing service organization, the senior management must intervene in the outsourcing process. Can maintain timely communication. At the same time, senior management should fully seek the opinions of employees and do auxiliary work, and must also monitor and evaluate the service quality of outsourcing service companies.

4. After the outsourcing of the enterprise's human resources strategic planning, after the enterprise outsources some functions, the human resources can be more engaged in strategic human resources work, so that the original functional department is gradually transformed into the strategic department of the enterprise, so that more and more Participate in the formulation of corporate strategies, expand business activities, lead corporate change, assume the role of employee advocates, assume the role of corporate social responsibility promoter, and be responsible for employee performance and corporate culture.