1. High temperature resistant tape is mainly suitable for metal surface treatment of computer cases, cabinets, etc., to protect the high temperature powder from spraying and baking paint.

2. At the same time, high-temperature tape is also suitable for electronic products, automotive industry, coating and other products. When high-temperature spraying, it plays a role of shielding, protection and insulation.

3. High temperature resistant tape will be fixed during the production of printed circuit boards, electronic parts, resistors and capacitors, and during the process of PCB impregnation, it will shield the gold fingers and prevent the plating solution from immersion and pollution. The printed circuit board gold plating has shielding protection. A certain effect.

4. Household appliances, machinery, electronics and other industries also need high-temperature coating and spray paint protection, high-temperature binding and fixing, and high-temperature adhesive tape can solve these problems.

5. High temperature resistant tape is sometimes used as a release paper joint, referred to as connecting tape.

6. It can be used in the drum of sizing machine, thermoplastic demoulding and other industries. The high temperature resistant tape can be used repeatedly and is easy to replace.

7. High temperature resistant tape is widely used in packaging, thermoplastic, compounding, sealing and heat sealing, electronic and electrical industries.

8. Mainly used in the electronics industry. The temperature resistance is usually between 120° and 260°. The high temperature resistant tape is often used for painting, baking varnish leather processing, coating masking and fixing in the manufacturing process of electronic parts, printed circuit boards and high temperature processing masks.

1. The life cycle of the Fiber Jumper industry. Through the market growth rate, demand growth rate, product variety, number of competitors, technological changes, and user purchase behavior of the Fiber Jumper industry, the development stage of the industry is judged.

2. The market supply and demand balance of Fiber Jumper industry. By studying the supply and demand status of the Fiber Jumper industry, as well as the import and export status, the supply and demand balance of the industry is judged, in order to grasp the degree of industry market saturation.

3. The competitive landscape of the Fiber Jumper industry. Through the analysis of the bargaining power of suppliers in the Fiber Jumper industry, the bargaining power of buyers, the ability of potential competitors to enter, the ability of substitutes, and the current competitiveness of competitors in the industry, we can grasp the five factors that determine the profit level of the industry. Kind of power.

4. Economic operation of Fiber Jumper industry. Mainly for data analysis, including the number of competing companies in the Fiber Jumper industry, the number of employees, total industrial output value, sales output value, export value and other aspects.

5. The main market competition enterprise in the Fiber Jumper industry. Including the company's products, business status, financial status, competitive strategy, market share, competitiveness analysis, etc.

6. Analysis of investment, financing and mergers and acquisitions. Including investment and financing project analysis, merger analysis, investment area, investment return, investment structure, etc.

7. Marketing of Fiber Jumper industry. Including marketing concept, marketing model, marketing strategy, channel structure, product strategy, etc.

Nanocrystalline magnetic cores have high magnetic permeability, high full magnetic induction, low coercivity, and low loss. Suitable for EMC/EMI filter common mode inductors, high frequency transformers, frequency converters, current transformers and other occasions. In the field of new energy, such as solar inverters, wind power generation and other occasions have also been widely used.

Nanocrystalline magnetic cores have extremely high magnetic permeability. It is mainly used for mobile phone wireless charging receiving terminal, shielding electromagnetic interference to mobile phones, reducing energy loss and improving charging efficiency. It can also be used in other wireless charging areas, such as car wireless chargers. The thinnest thickness of the nanocrystalline magnetic sheet can reach 0.1mm, and the thickness can also be added to achieve higher functions. Various standards and shapes can be customized according to customer needs.

Nanocrystalline cores for common mode inductors, high permeability, used for EMC common mode inductors, EMI filters.

Nanocrystalline magnetic cores have extremely high magnetic permeability, wide frequency characteristics, and still have high magnetic permeability up to 30MHz high frequency. It is very suitable for EMC filters and common mode inductors to suppress common mode noise. Compared with traditional soft magnetic materials, such as ferrite cores, nanocrystalline cores have obvious advantages, high inductance, good filtering, small size, fewer copper turns, and high efficiency and energy saving.

Epoxy-coated nanocrystalline magnetic cores are smaller than boxed magnetic cores, require less copper wires, lower copper losses, reduce costs, save energy and save space. It is suitable for miniature filter common mode inductor, ISDN network transformer, network filter, EMC filter, IGBT/Mosfet drive transformer, high-definition camera signal transmission transformer/filter.

New energy electric vehicle DC bus dedicated nanocrystalline cores, customized EMC oval amorphous nanocrystalline cores, frequency converter EMI cores

The elliptical nanocrystalline core is mainly used for common-mode filter inductors, which facilitates directly passing through the bus. It is mainly used between the inverter and the motor to filter high-frequency noise to protect the inverter and motor bearings. It is widely used in new energy electric vehicle powertrains and charging stations.

Nanocrystalline block core, nanocrystalline block is made of 25 micron thick nanocrystalline ribbon. Nanocrystalline block has the characteristics of low core loss and high magnetic permeability. It is suitable for high-frequency transformers, inductors, sensors, and wind turbines.

Nanocrystalline C-core, amorphous C-core upgraded product, with high full magnetic flux density, low coercivity, low core loss, very low noise, high frequency up to 20KHz, suitable for main transformer, output inductance, boost PFC Choke. Can replace ferrite cores. Standards can be customized.

Amorphous and nanocrystalline void cores are suitable for high current output inductors, PFC chokes, differential mode chokes, Hall effect sensor concentrators, and have the first-class benefits of full magnetic flux density and low core loss.

1. Analysis of the production capacity of the fiber optic connector adapters industry. It refers to the statistical analysis of the total amount of goods that a producer can produce and the total amount of goods produced in a certain period; at the same time, it analyzes the capacity and output structure of the fiber optic connector adapters industry during this period.

2. Import and export analysis of fiber optic connector adapters industry. It refers to the analysis of the import and export volume, import and export structure, and import and export price trend of the fiber optic connector adapters industry during the same period of statistical analysis.

3. Analysis of inventory and self-consumption in the fiber optic adapter industry..jpg)

4. Analysis of the supply of fiber optic connector adapters industry. The market supply is not equal to the production, because a part of the production is used by the producers for their own consumption as a reserve or export, and a part of the supply can be imported goods or used reserve goods.

5. Analysis of the needs of the fiber optic adapter industry. It refers to the statistical analysis of the total demand for the fiber optic connector adapters industry in the downstream market during the above period; at the same time, the analysis of the demand scale, demand structure and the regional structure of the total demand of the downstream industry during this period.

6. Analysis of factors affecting the supply of fiber optic connector adapters industry. Including price factors, substitute factors, production technology, policies, and downstream industry development.

7. Analysis of factors affecting the demand of the fiber optic connector adapters industry. Including changes in disposable income, changes in personal preferences, borrowing and its costs, changes in prices of substitutes and complements, population size and structure, expectations for the future, changes in education levels, etc.

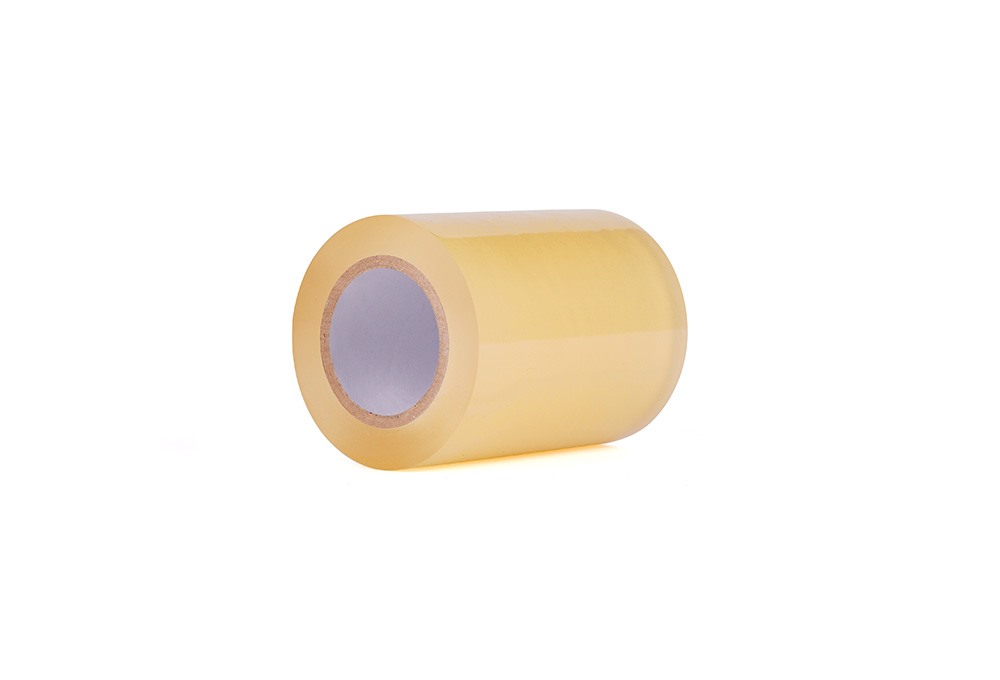

Generally speaking, the double sided duct tape products produced by regular manufacturers are qualified and have no peculiar smell. The poor quality double sided duct tape generally has a peculiar smell, and its retention is very poor, especially in a low temperature environment, the tape is very easy to crack and quickly lose its adhesion, this kind of tape is definitely a defective product.

The color of defective double sided duct tape will be much darker than qualified tape, and when touched by hand, generally defective tape will be harder, and since the film is compared, the actual number of meters will definitely be reduced. Good double sided duct tapes have softer films and good tensile properties. Therefore, the brightness and thickness of the tape film are very important, and must be carefully checked when purchasing.

The whiter the appearance of the double sided duct tape, the less the impurities of the tape, so as to ensure the normal adhesiveness. The tape products below 100 meters have a certain degree of transparency and the paper tube can be seen. The defective tape is generally yellowish, and irregular white spots are scattered on the surface. When squeezed by hand, there will be impurities or dry glue marks that cannot be removed. The manufacturing process of defective double sided duct tape must be very rough, so the color of the tape will definitely be yellowish. Therefore, when purchasing double sided duct tape, you must pay attention to the above items and check carefully.