The deployment of fiber optics in telecommunications and wide area networking has been common for many years, but more recently fiber optics have become increasingly prevalent in industrial data communications systems as well. Fiber optic technology uses pulses of light to carry data along strands of glass or plastic. It's the technology of choice for the government's National Broadband Network (NBN) and data centers, which promises to deliver next-generation 200G and 400G Ethernet speeds.

When talking about 'speed', we were actually talking about throughput (or capacity) — the amount of data you can transfer per unit time, says Associate Professor Robert Malaney from the University of New South Wales, School of Electrical Engineering and Telecommunications.

And fiber optics can definitely transfer more data at higher throughput over longer distances than copper wire. For example, a local area network using modern copper lines can carry 3000 telephone calls all at once, while a similar system using fiber optics can carry over 31,000.

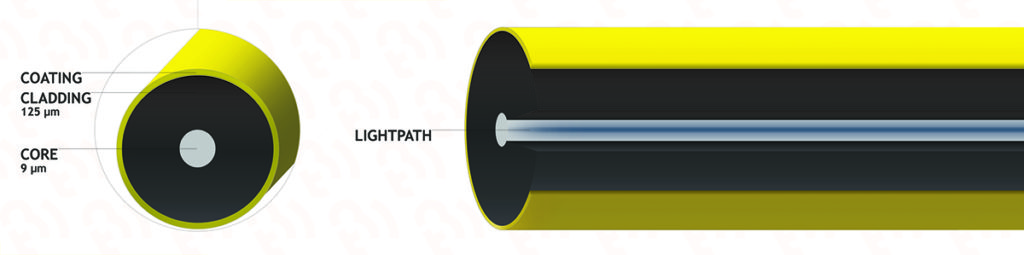

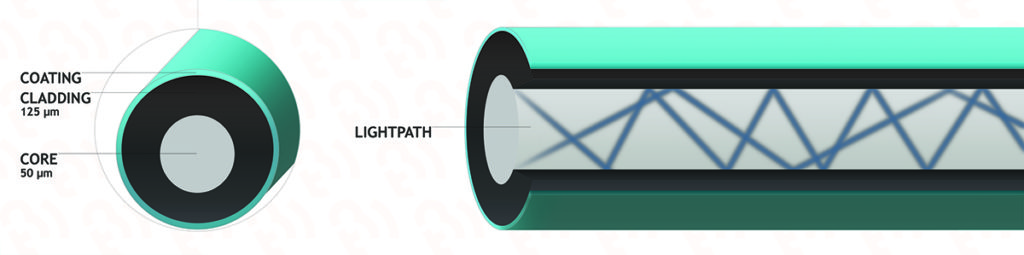

So what gives it the technical edge over copper wires? Traditional copper wires transmit electrical currents, while fiber optic technology sends pulses of light generated by a light emitting diode or laser along optical fibers.

In both cases you're detecting changes in energy, and that's how you encode data. With copper wires you're looking at changes in the electromagnetic field, the intensity of that field and perhaps the phase of the wave being sent down a wire. With fiber optics, a transmitter converts electronic information into pulses of light — a pulse equates to a one, while no pulse is zero. When the signal reaches the other end, an optical receiver converts the light signal back into electronic information.

The throughput of the data is determined by the frequency range that a cable will carry — the higher the frequency range, the greater the bandwidth and the more data that can be put through per unit time. And this is the key difference — fiber optic cables have much higher bandwidths than copper cables (eg. cat5e copper cable).

"Optical fiber can carry much higher frequency ranges — note that light is a very high frequency signal — while copper wire attenuates or loses signal strength at higher frequencies," says Malaney.

Also, fiber optic technology is far less susceptible to noise and electromagnetic interference than electricity along a copper wire.

"You can send the signal for over 200 km without any real loss of quality while a copper cable signal suffers a lot of degradation over that distance," says Malaney.

As well as a significant increase in connection speed, fiber optic networks offer a tremendous capacity to keep up with any new technological advances. Once the basic fiber optic infrastructure is in place, it can be rearranged and the end point electronics upgraded when necessary, to deliver even higher capacity. It can do this far more effectively than existing wireless or copper based systems.

In terms of its serviceable lifetime, glass (from which fiber optic cable is made) is long lasting, stronger than copper and more able to retain its transmission properties after physical stress such as weight strain, or even attack by rats and cockatoos. We install fiber differently from copper: in good quality coatings, inside ducts, or in the case of newer systems, encased entirely by electrical transmission wires.

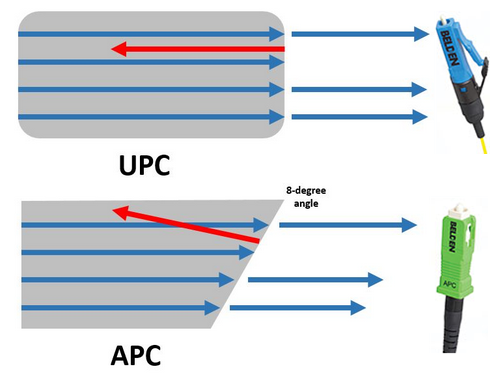

For applications where signal security is a concern, fiber optic technology is an excellent solution. Fiber optic cables do not generate electromagnetic fields that could be picked up by external sensors. It is also more difficult to 'steal' signals by spicing into optical fibers than it might be with conventional copper wiring.