An fiber optic splitter is an essential component used in an FTTH PON where a single optical input is split into multiple output. This enables the deployment a Point to Multi Point (P2MP) physical fiber network with a single OLT port serving multiple ONTs. The most common split ratios are 1:2, 1:4, 1:8, 1:16 and 1:32. Although other split ratios are available, they are usually custom made and commands a premium. Fiber optic splitters enable a signal on an optical fiber to be distributed among two or more fibers. As a basic example, the diagram below shows how light in a single input fiber can split between four individual fibers (1x4):

Splitters can be built using a variety of single mode and multimode optical fibers and with most connector types for various applications. From a technology standpoint, there are two commonly used types of optical splitters:

- Fused Biconic Tapered (FBT)

- Planar Lightwave Circuit (PLC)

As with most technology, each type has both advantages and disadvantages when deploying them in a passive optical network.

FBT is the traditional technology in which two fibers are placed closely together and fused together by applying heat while the assembly is being elongated and tapered. A signal source is used to determine the point at which the desired coupling ratio has been met, which then stops the process.

As this technology has been developed over time, the quality of FBT splitters is very good and they can be deployed in a cost-effective manner. FBT splitters are widely accepted and used in passive networks, especially for instances where the split configuration is smaller (1x2, 1x4, etc).

A drawback of this technology occurs when larger split configurations (1x16, 1x32, 1x64, etc) are required. FBT technology is limited in the number of quality splits that can be achieved in a single instance, so several must be spliced together when a larger split configuration is required. As a result, the physical size increases due to multiple splitters, along with the excess loss from the splices. Thus, for these instances, PLC splitters are more ideal as we will discuss in the next section.

PLC (Planar Lightwave Circuit) Splitters are Single Mode Splitters with an even split ratio from one input fiber to multiple output fibers. Available split counts are: 1x4, 1x8, 1x16, and 1x32. PLC Splitters are availble with 900µm loose tube singlemode fiber and terminated or unterminated as per your needs. Unconnectorized PLC splitters come with no connectors for easy splicing or connectorization. Connectorized PLC splitters are available with your choice of Fiber Optic Connectors: LC/UPC, LC/APC, SC/UPC, SC/APC, FC/UPC, FC/APC, and ST/UPC.

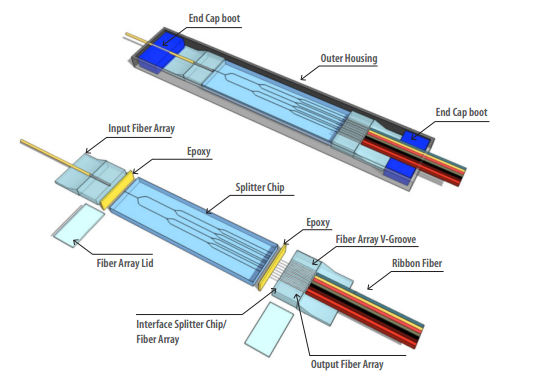

Among the many miniature parts which makes up a passive optical PLC splitter, there are three main components which are the fiber array for the input and output, and the chip. The design and assembly of these three component is the key to produce a high quality PLC splitter.

A more recent technology, PLC splitters offer a better solution for applications where larger split configurations are required. To achieve this, waveguides are fabricated using lithography onto a silica glass substrate, which allows for routing specific percentages of light. As a result, PLC splitters offer very accurate and even splits with minimal loss in an efficient package.

With the rapid growth of FTTx worldwide, the requirement for larger split configurations (1x32, 1x64, etc) in these networks has also grown in order to serve mass subscribers. Due to the performance benefits and overall low cost to deploy, PLC splitters are now the ideal solutions for these types of applications.

※コメント投稿者のブログIDはブログ作成者のみに通知されます