Tungsten heavy alloys, also called WHAs, Virtually all commercial WHAs are two-phase materials, with the principal phase being nearly pure tungsten in association with a binder phase containing transition metals plus dissolved tungsten.

WHA provides a very high density, as is apparent when compared to other metals, as shown in the table as follows:

WHAs was once referred to as “tungsten heavy metals,” but that nomenclature has been largely abandoned so as to avoid confusion with toxic heavy metals such as Pb, Hg, and others with which WHAs have no relation. While the primary selection is made on the basis of very high density, WHA provides tungsten alloy manufacturers a unique set of associated engineering benefits which includes:

• Low toxicity, low reactivity surface character

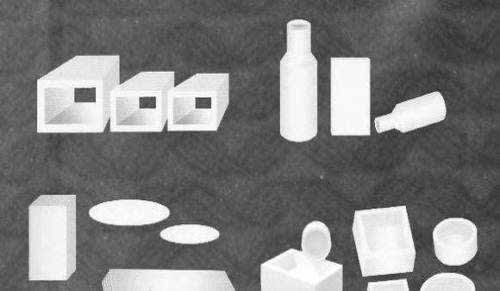

• Ability to be custom manufactured in a wide range of sizes and shapes

• Readily recycled for economy and environmental friendliness.

• Strength comparable to many medium carbon steels

• Ability to be machined with common shop tools and techniques

• High elastic stiffness

• Low CTE in combination with relatively high thermal conductivity

Due to these characteristics, as an ideal material, WHA is widely used for new mass property applications as well as the replacement of Pb or U in existing applications.

As a consequence, WHAs display a unique property set derived from both components — their fundamental properties resulting from those of the principal tungsten phase. The selection of a WHA for a given application is typically made on the basis of very high density — whether gravimetric or radiographic.

Tungsten heavy alloys are distinctly different from related materials such as pure tungsten metal and cemented carbides (most commonly WC-Co). Only very rarely could one material be used as a substitute for another. WHA provides many of the properties of pure W, yet in a form that provides:

• Lower fabrication cost due to the reduced sintering temperature,

• A greater range of both size and shape can be manufactured due to full density attainment via liquid phase sintering (LPS) as opposed to final densification by post-sinter thermomechanical processing,

• Generally improved machinability,

• Preservation of desirable properties of pure tungsten.

Tungsten heavy alloys are not related to “tungsten (T grade) steels.” In difference to pure W however, tungsten heavy alloys are not high temperature materials. Elevated temperature properties of WHA are strongly influenced by the lower melting temperature binder phase.

For more information, please visit http://www.samaterials.com/

WHA provides a very high density, as is apparent when compared to other metals, as shown in the table as follows:

WHAs was once referred to as “tungsten heavy metals,” but that nomenclature has been largely abandoned so as to avoid confusion with toxic heavy metals such as Pb, Hg, and others with which WHAs have no relation. While the primary selection is made on the basis of very high density, WHA provides tungsten alloy manufacturers a unique set of associated engineering benefits which includes:

• Low toxicity, low reactivity surface character

• Ability to be custom manufactured in a wide range of sizes and shapes

• Readily recycled for economy and environmental friendliness.

• Strength comparable to many medium carbon steels

• Ability to be machined with common shop tools and techniques

• High elastic stiffness

• Low CTE in combination with relatively high thermal conductivity

Due to these characteristics, as an ideal material, WHA is widely used for new mass property applications as well as the replacement of Pb or U in existing applications.

As a consequence, WHAs display a unique property set derived from both components — their fundamental properties resulting from those of the principal tungsten phase. The selection of a WHA for a given application is typically made on the basis of very high density — whether gravimetric or radiographic.

Tungsten heavy alloys are distinctly different from related materials such as pure tungsten metal and cemented carbides (most commonly WC-Co). Only very rarely could one material be used as a substitute for another. WHA provides many of the properties of pure W, yet in a form that provides:

• Lower fabrication cost due to the reduced sintering temperature,

• A greater range of both size and shape can be manufactured due to full density attainment via liquid phase sintering (LPS) as opposed to final densification by post-sinter thermomechanical processing,

• Generally improved machinability,

• Preservation of desirable properties of pure tungsten.

Tungsten heavy alloys are not related to “tungsten (T grade) steels.” In difference to pure W however, tungsten heavy alloys are not high temperature materials. Elevated temperature properties of WHA are strongly influenced by the lower melting temperature binder phase.

For more information, please visit http://www.samaterials.com/