Most people want to learn more about the 'soft' and 'slippery' crystalline nature of boron nitride, because of this special property, Hot Pressed Boron Nitride is used in lubricants and cosmetic preparations.

Firstly, we must know the definition of boron nitride.

What is Boron nitride?

Boron nitride (BN) was first found in 1840's by an English chemist, W.H.Balmain, by using molten boric acid and potassium cyanide, but unfortunately, he found that this new compound was un‐stable and required many methods to obtain a stable boron nitride.

For nearly a hundred years studies on boron nitride remained in laboratory scale due to the technical difficulties of different production techniques and high cost of the material which is obtained with these synthetic methods but in 1950's Carborundum and Union Carbide companies tried to obtain high purity boron nitride powder on an industrial scale and fabricated shaped parts of boron nitride for commercial applications with sophisticated hot pressing techniques.

What are the Properties of hexagonal boron nitride?

There are the main boron nitride properties as follows:

Non toxicity,

Easily machinability- non-abrasive and lubricious,

Chemical inertness,

Non-wetting by most molten metals,

High thermal conductivity,

Low thermal expansion,

Good thermal shock resistance,

High electrical resistance,

Low dielectric constant and loss tangent,

Microwave transparency.

Hexagonal boron nitride is being widely used because of its unique combination of properties which include:

Chemical inertness (corrosion resistance against acids and molten metals),

High temperature stability (melting point near 2600ºC),

Low density (2.27 g.cm-3 theoretical density),

Stability in air up to 1000ºC (in argon gas atmosphere up to 2200ºC and in nitrogen up to 2400ºC), Stability to thermal shock,

Easy workability of hot-pressed shapes,

Excellent electrical insulating character

Very high thermal conductivity.

As a thermal conductor, BN ranks with stainless steel at cryogenic temperatures and with beryllium oxide, BeO, at elevated conditions; above 700ºC, the thermal conductivity of hexagonal boron nitride exceeds that of toxic BeO.

The particular interest are its good dielectric properties (dielectric constant is 4, i.e half of that of α-Al2O3 ), also high dielectric strength and its ability to lubricate over a wide range of temperatures.

Its small coefficient of friction is retained up to 900ºC, whereas other solid lubricants like graphite and molybdenum disulphide are burnt away at lower temperatures.

Because of its high temperature stability and inertness against carbon and carbon monoxide up to 1800ºC it is as a refractory ceramic superior to the nitride ceramics Si3N4 and AlN and the oxide ceramics magnesium oxide, CaO, zirconia. ,

Due to its non-wetting properties it is stable to attack by molten glass, molten silicon, boron, nonoxidizing slags, molten salts (borax, cryolite) and reactive metal melts (e.g Al, Fe, Cu, Zn).

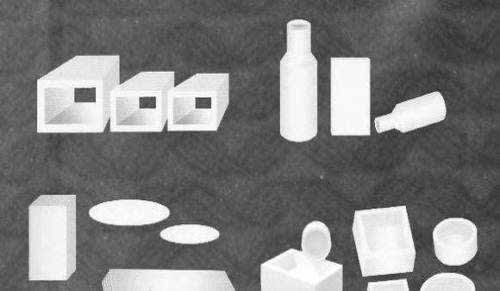

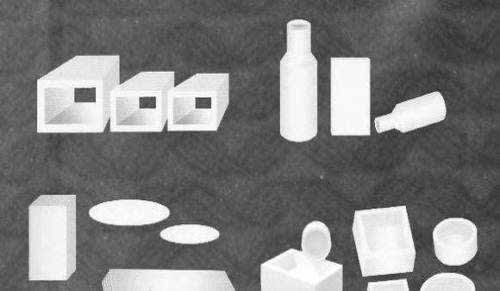

Because of its poor sinterability, dense shapes of hexagonal boron nitride are obtained almost exclusively by hot-pressing.

It must be recognized that the most chemical and physical properties of axial hot-pressed BN shapes depend on the nature and the amount of additives used for densification (up to 6 wt. % of B2O3, metal borates or SiO2 ).

Further some thermal (coefficient of expansion, thermal conductivity) and mechanical (flexural strength, Young's modulus) property values vary according to the direction of hot-pressing, BN being similar to graphite in respect of anisotropy.

By hot-pressing isostatic of canned boron nitride powder, theoretically dense and pure hot pressed boron nitride shapes without texture and with improved properties can nowadays be obtained.

For more information, please visit http://www.samaterials.com/

Firstly, we must know the definition of boron nitride.

What is Boron nitride?

Boron nitride (BN) was first found in 1840's by an English chemist, W.H.Balmain, by using molten boric acid and potassium cyanide, but unfortunately, he found that this new compound was un‐stable and required many methods to obtain a stable boron nitride.

For nearly a hundred years studies on boron nitride remained in laboratory scale due to the technical difficulties of different production techniques and high cost of the material which is obtained with these synthetic methods but in 1950's Carborundum and Union Carbide companies tried to obtain high purity boron nitride powder on an industrial scale and fabricated shaped parts of boron nitride for commercial applications with sophisticated hot pressing techniques.

What are the Properties of hexagonal boron nitride?

There are the main boron nitride properties as follows:

Non toxicity,

Easily machinability- non-abrasive and lubricious,

Chemical inertness,

Non-wetting by most molten metals,

High thermal conductivity,

Low thermal expansion,

Good thermal shock resistance,

High electrical resistance,

Low dielectric constant and loss tangent,

Microwave transparency.

Hexagonal boron nitride is being widely used because of its unique combination of properties which include:

Chemical inertness (corrosion resistance against acids and molten metals),

High temperature stability (melting point near 2600ºC),

Low density (2.27 g.cm-3 theoretical density),

Stability in air up to 1000ºC (in argon gas atmosphere up to 2200ºC and in nitrogen up to 2400ºC), Stability to thermal shock,

Easy workability of hot-pressed shapes,

Excellent electrical insulating character

Very high thermal conductivity.

As a thermal conductor, BN ranks with stainless steel at cryogenic temperatures and with beryllium oxide, BeO, at elevated conditions; above 700ºC, the thermal conductivity of hexagonal boron nitride exceeds that of toxic BeO.

The particular interest are its good dielectric properties (dielectric constant is 4, i.e half of that of α-Al2O3 ), also high dielectric strength and its ability to lubricate over a wide range of temperatures.

Its small coefficient of friction is retained up to 900ºC, whereas other solid lubricants like graphite and molybdenum disulphide are burnt away at lower temperatures.

Because of its high temperature stability and inertness against carbon and carbon monoxide up to 1800ºC it is as a refractory ceramic superior to the nitride ceramics Si3N4 and AlN and the oxide ceramics magnesium oxide, CaO, zirconia. ,

Due to its non-wetting properties it is stable to attack by molten glass, molten silicon, boron, nonoxidizing slags, molten salts (borax, cryolite) and reactive metal melts (e.g Al, Fe, Cu, Zn).

Because of its poor sinterability, dense shapes of hexagonal boron nitride are obtained almost exclusively by hot-pressing.

It must be recognized that the most chemical and physical properties of axial hot-pressed BN shapes depend on the nature and the amount of additives used for densification (up to 6 wt. % of B2O3, metal borates or SiO2 ).

Further some thermal (coefficient of expansion, thermal conductivity) and mechanical (flexural strength, Young's modulus) property values vary according to the direction of hot-pressing, BN being similar to graphite in respect of anisotropy.

By hot-pressing isostatic of canned boron nitride powder, theoretically dense and pure hot pressed boron nitride shapes without texture and with improved properties can nowadays be obtained.

For more information, please visit http://www.samaterials.com/

※コメント投稿者のブログIDはブログ作成者のみに通知されます