YOUR PET preform is often a long, hollow tube which is used for various forms of bottles and keepers. The mouth belonging to the PET preform 30MM 30/25 PET Preform is like the mouth with the finished bottle. In the process of manufacturing a new PET bottle, the PET preform is poured suitable mould that includes a unique shape. The final bottle may have a similar mouth to the one which the PET preform provides. It is utilized to manufacture many types of bottles plus containers.

The PET preform is actually heated to 110 degC and handed to a negative mold that holds the theory of the actual bottle. Compressed air is then employed to stretch the preform to length. The process all together cools the preform. A two-stage tensile impact molding process subsequently converts the preform right PET bottle. Your PET bottle is definitely then stacked along with foiled. Once the PET bottle continues to be produced, it will probably be packaged.

The production process to get a PET preform includes several steps. The preform is heated to 110 degC and then passed to a poor shape, which holds the form of the genuine bottle. Compressed surroundings stretches the preform plus simultaneously cools it. Afterward, the PET wine bottle is blown out of the mold, where it can be foiled and stacked to accomplish the production process. This process has been a popular choice regarding PET bottle manufacturers.

The process of building a PET preform entails injection moulding. Injection moulding can be a process where molten plastic is forced in to a hollow metal bit. The molten cheap fills the mildew under pressure and hardens in the shape of your mould. The PET preform is then placed into your container. The final product is like the original. You'll find no problems with using this preform. The new process can be a big time saver for both the producer and the conclusion consumer.

A PET preform is usually a popular material with regard to plastic bottles. By far the most common uses for the PET preform consist of soaps, shampoos, and also food products. The process can also be used to produce test tubes, which are commonly used intended for liquids. If its made to the complete specification, PET preforms is often converted to a test tube. The procedure for manufacturing a FAMILY PET preform is complex and involves a number steps.

The means of making a FAMILY DOG preform is sophisticated, but it can be carried out in a quantity of ways. The Bottle Cap Mould process starts with the design of the particular PET preform would mould itself. It is actually divided into a couple of halves. The two halves are attached to backing plates which can be drilled so in which steam and soothing water can taste. The backing china also contain guide pins to assist align the two halves. These factors form a FAMILY DOG preform mould.

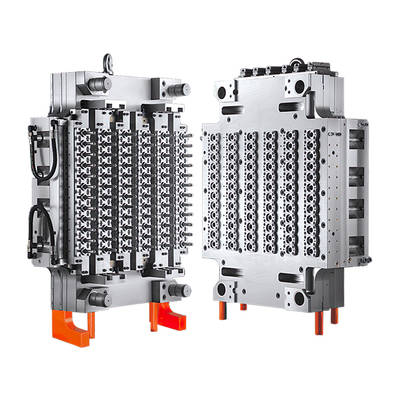

Establishing advanced preform moulds may be the core business involving Indian PETform. Provides hot-runner systems China Cap Compression Molding Machine Manufacturers with up to 144 cavities. On K2019, they introduced a new hot-runner development. These kind of molds feature greater insulation. The advanced materials utilised in these molds are titanium and ceramics, which reduce energy ingestion by 15 for you to 20%. These materials include lower thermal conductivity compared to steel, and can be biodegradable.

In supplement to multicavity moulds, GDXL Precise Systems designs and producers high-cavity PET moulds for your plastics industry. They are developing business since 1993, and also their products include single and double-cavity PUPPY blow moulds. They may be configured for as long as 144 cavities and come in several different neck finishes and material technologies. They also offer a selection of neck finishes to match different processes.

Whether your product or service requires a high-cavity mould that has a high-volume production charge or a small-scale manufacturing process, Rompa is sure to have a multi-cavity mould to chic. The experts at Rompa will continue to work with you to find out which type regarding multicavity mould can best meet ones production goals along with minimize waste. Consequently, what are the top features of pet moulds?

The caliber of PET Preform Moulds is just like that of the approaches made in The us. The moulds are manufactured when using the same quality elements as in the us. In addition in order to high-quality materials, each PET Preform Mould can be easy to manage. With a combination of designs and cavity cavities, it can be practical, no matter what exactly your production ambitions. You can even make your own multicavity plastic products effortlessly.

In case you're producing lots of products, you need a multicavity PUPPY preform mould to improve your production ability. The patented optiRUN technological know-how from MHT Mold & Hotrunner Technological know-how AG greatly minimizes the formation associated with PET dust. This dust is produced by gaseous PET fission products about the metallic tool outside. So, the nozzles could effectively prevent this formation of toxic particles on the mould.

A Multicavity Pet Moulds are employed to produce huge volumes of goods. It is easy to use and requires little maintenance. The molds are constructed with high-quality aluminium, that is certainly suitable for hot-filling generation. It is also works with various PET wine beverages. The range of different cavities allows you to create many izes and shapes. These moulds come in many sizes, from TWELVE to 144.

Made for mid-size and a number of package markets, the Husky NexPET mould could be operated on a few preform molding platforms. It has a lengthier vertical pitch range of 60 mm and may accommodate thread diameters as long as 40 mm. Their special design company offers photochemical etching, milling, eroding, and laser engraving, which will help uou achieve the perfect designs for ones pet packaging.

ANY 28mm Cap Mould can often manufacture a plastic bottle cap. This is a good choice for making sports drinks, sodas, and soft drinks. It can as well be used with regard to other bottles, which include milk bottles as well as water bottles. It will come in various sizes, including 30mm, 38mm, and also 48mm. It can also be customized to fit just about any bottle cap. It's got numerous benefits, and can be a great addition for you to any business.

A 28mm neck of the guitar plastic bottle could be made using the Plast Cap Would mould. The 28mm plast cap mould is constructed of new HDPE material allowing it to be custom fashioned. A high-quality Plast Cap mould can be a valuable investment for a business that creates sports drinks. The durability, precision, and affordability ensure it is the ideal option for sports wine beverages. This mould can be highly efficient, cutting down labor and public resource costs.

A 28mm neck of the guitar plast cap mould is done from 100% innovative HDPE material. It can be easily customized as well as used for physical activities drinks, soft food and drink, and other beverages. It is furthermore highly durable, and is very useful both standard along with custom designs. The tailed-made alternative from SINOPK assists you design the great bottle cap mould for the business. You can choose from numerous mould materials in addition to colors.

A 28mm fretboard plast cap mould is made of high-quality HDPE materials. It can be customized for your specific requirements. This can be a great choice for virtually any company that desires to add more features recommended to their products. These features allow it to be a great choice for customizing and producing bottles. Addititionally there is no need to replace the truck tops because this mold is completely custom. It is a smart choice for any packaging company.

A 28mm the neck and throat plast cap mould consists of 100% new HDPE materials. The process of having a 28mm neck plastisol covering mould is fast and simple. A customized product can help you save time and cash. You can tailor-make your bottle hats and create your individual brand identity. There are use your unique design! It is not optional to remember that quality and performance are vital towards your business. The right tool will increase your bottom line and help you meet your pursuits.

A 28mm fretboard plast cap mould can help you save major time and money. A high-quality mould China Preform Mould Factory can grow your production by around 50%. And, it's easy to customize. There are a couple of main advantages to using a custom-designed cap mould. First, it offers you a higher production rate. It is an investment which will pay off eventually. So, if you would like to be more competitive in the market, consider some sort of custom-made mould.

Getting advanced preform moulds could be the core business of Indian PETform. They feature hot-runner systems China Pet Mould Manufacturers with around 144 cavities. On K2019, they introduced a fresh hot-runner development. These molds feature elevated insulation. The advanced materials included in these molds will be titanium and ceramics, which reduce energy ingestion by 15 that will 20%. These materials get lower thermal conductivity in comparison with steel, and can even be biodegradable.

In add-on to multicavity moulds, GDXL Precise Equipment designs and products high-cavity PET moulds for your plastics industry. They have been around in business since 1993, in addition to their products incorporate single and double-cavity FAMILY DOG blow moulds. They may be configured for around 144 cavities and come in many different neck finishes in addition to material technologies. They also offer a selection of neck finishes to check different processes.

Whether your supplement requires a high-cavity mould having a high-volume production rate or a small-scale development process, Rompa will have a multi-cavity mould to chic. The experts at Rompa will work with you to view which type of multicavity mould can best meet your production goals and minimize waste. And so, what are the top features of pet moulds?

The grade of PET Preform Moulds is the same as that of the methods made in Canada. The moulds are manufactured with all the same quality materials as in america. In addition that will high-quality materials, each PET Preform Mould is usually easy to keep. With a wide selection of designs as well as cavity cavities, it can chic, no matter just what your production goals. You can even make your own personal multicavity plastic products easily.

In case you are producing a considerable amount of products, you need a multicavity FAMILY DOG preform mould to generate your production capability. The patented optiRUN technology from MHT Style & Hotrunner Engineering AG greatly minimizes the formation associated with PET dust. This dust is made by gaseous PET fission products for the metallic tool exterior. So, the nozzles might effectively prevent the particular formation of toxic particles through the mould.

A Multicavity Pet Moulds are widely-used to produce huge volumes of goods. It is easy to use and requires tiny maintenance. The molds are constructed with high-quality aluminium, that's suitable for hot-filling creation. It is also best with various PET bottles. The range connected with different cavities allows you to create many size and shapes. These moulds can be found in many sizes, from TEN to 144.

Ideal for mid-size and many package markets, the Husky NexPET mould can be operated on a ton of preform molding stands. It has a lengthier vertical pitch long distance of 60 mm allowing it to accommodate thread diameters approximately 40 mm. The special design provider offers photochemical etching, milling, eroding, along with laser engraving, which can assist you achieve the perfect designs to your pet packaging.

Should you have questions about the plastic surgery, you should ask a cosmetic surgeon. The American Culture of Plastic Surgeons incorporates a section dedicated Pet Mould Suppliers that will patient questions. That member surgeons response patients' questions plus share their suffers from. You can furthermore ask a question to the Ask a Medical specialist forum. You can purchase answers to a lot of questions about your surgery in the area. Regardless of your basis for asking, there is often a surgeon who may answer your query.

There are many types of Plastic Deal with Moulds available. Choose one that suits your family needs and the distinct products that you intend to manufacture. You require a mold that has a clamping system that will prevents the pins from colliding with all the slides. The ejection method will push the actual solidified part outside the open cavity from the mould. These mechanisms are very important because many people prevent the segments from sticking together when they are opened.

The procedure of producing your two-color lighter cope with uses a two-color treatment mould. A two-color treatment molding machine includes two separate groupings of injection gadgets and nozzles. That mold produces mostly two-colored products. This technique reduces post-processing period and assembly moment. These products might have better aesthetics and added value when compared to a single-colored supplement. This method must be used to manufacture two-color lighter in weight handles.

Two-color injection molding is the word for the process with molding products making use of two different colors. The machines utilized in this process have separate groups involving nozzles and injection units. These moulds generate mostly two-color items. This method preserves post-processing time and reduces the quantity of steps involved with assembly. This practice also adds benefit to products. Considering that 1970s, two-color lighter handles have grown to be commonplace, and are used all over the world.

The two-color injection molding process consists of the injection of two different colors into your same mould. The products are usually cut from the same kind of plastic. This process minimizes assembly time and post-processing by means of a two-color plastic-type handle mould. The two-color shot molding method as well helps create products which may have a better conceptual appeal and put in value. This technique is traditional in manufacturing lighters, together with oil and drinks bottle handles.

A plastic handle mould is usually a popular choice with regard to replacements of destroyed metal bottles. The majority of two-color lighter addresses use rotating shafts, allowing the mould to be rotated to insert an additional color. Using using these services is very cost-effective for the reason that process does not require post-processing. Which is ideal for substitute parts for acrylic and beverage containers. If you are in the market for a replacement for the broken metal bottle, this method can assist you replace the part without breaking the financial institution.

When it relates to the two-color shot process, the plastic handle mould is often a useful tool for manufacturing a range of products. It can also be used to creation water and petrol bottle handle. The specification of products usually amounts from 1L to help 20L. Typically, it comes in a variety of shapes and forms. You can actually design the manage shape yourself, if you can help it become in two hues. The mould can be used to manufacture lighters which has a rotating shaft.