Comparison between Magnetic and Optical

Rotary Encoders, Incremental

In General

Both Magnetic Encoder and Optical Encoder have their own strong points and week points. You can not tell which is better in general. Depending on applications and environments, one can be better than the other.

Optical one has longer history and it is lower in the cost in many cases. Magnetic ones are new and used less at this moment and the cost is higher in many cases but not always. You can not say optical one is always more economical than magnetic one.

Signal accuracy depends on how they are designed and magnetic one can output better signals than optical one depending on conditions. Following is the detailed explanation.

Non-Contact and Bearingless

Both magnetic and optical encoders can be non-contact type without using any bearing. However, magnetic encoder has more chances to be non-contact bearingless type than optical one. The reason is that a pulser( rotor) is not sandwiched by two parts like optical encoder most of the cases, A magneto-resistive sensor is placed at the circumference of rotor usually.

1) Stator, Enclosure or Housing

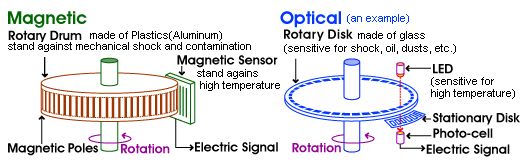

Magnetic encoders can be flat and thin and it can save space of axial direction while most of Optical ones are longer in axial direction and takes larger space. Magnetic one is with a drum pulsers(rotor) and a sensor placed around the circumference of rotor.

Optical one is with a disk pulsers sandwiched between LED and Photo-Cell without an exception.

Therefore, in the case of magnetic encoder, a sensor and an electric circuitry determine the dimension of axial direction as the sensor is longer than drum thickness. In the case of optical encoder, the dimension of axial direction is determined by a LED, a disk, a photo-cell and an electric circuitry.

In many cases, magnetic encoder has larger diameter than length and optical one has larger length than diameter. As far as the encoder diameter is smaller than a motor diameter, shorter length save a space.

2) Sensor

A sensor is attached to a stator.

Magnetic encoder has Magneto-Resistive Sensor and a Pulser. The sensor is strong against high (120 degree C) and low temperatures. The MR sensor can detect magnetic pulses from a magnetic pulser (rotor) by itself alone.

Optical encoder has a pulser in between a LED and a Photo-Cell. Photo-Cell detects LED originated pulsing lights with help of slits open on a pulser. The optical sensor is weak against higher temperature above 70 degree C because of LED.

3) Pulser (Rotor)

Magnetic pulsers are made of plastic magnet drums or magnets on aluminum drums. Magnetic rotors are strong against vibration, shock, oil mists, water, chemicals, dusts and etc.

Most of optical ones are made of glass and metal film and they are week against mechanical

shocks and any contaminants.

A pulser is placed close to a sensor.

4) Signal Accuracy

Both magnetic and optical encoders can output digital or analogue signals but digital ones are more popular. Usually, signals are A & B only or A, B and Z. The function of magnetic and optical encoders are identical mostly.

Signal accuracy depends not on magnetic or optical ones but on how an encoder is designed. It has been believed that optical one has higher accuracy but it is not always true. It is a matter of whether or not how magnetic poles or slits are made on rotors. It is a matter of pole pitch accuracy or slit pitch accuracy and a matter or whether or not interpolation or signal division is made.

It is true that slit pitches can be controlled easier than pole pitches but it does not mean optical one is always better than magnetic one. Whether or not signals are made directly from poles or slits without or less interpolation is an important factor. Magnetic encoder with higher accuracy than ordinary optical encoder can be made, depending on conditions.

5) Severe Environment

When it comes to severe environments, magnetic encoders have much better features. Magnetic ones are strong against high temperature, water, salt water, oil, oil mists, dusts, mechanical shocks and vibrations, etc while such mechanical shacks and contaminants are fatal to optical ones.

Why ?

Most important parts of magnetic encoder is MR Sensor and Magnetic Pulser( rotor) and they can stand against higher temperature than 150 degree C. The limiting factor is ICs or solders on electric circuitry. Therefore, depending on ICs put on circuitry, temperature range can be from -40 degree C to + 120 degree C or from -20 degree C to +90 degree C, for example. In addition, these parts are insensitive to many kinds of contaminants.

On other hand, optical encoder is limited by the most important part, LED, and it can survive from -20 degree C to +70 degree C for operation. Any kinds of contaminants are fatal for glass made pulser. Especially, oil mists never can be shut out even with the best shield.

6) Costs of Magnetic and Optical Encoders

The magnetic encoders with MR Sensors began to be used in early 1980s. Optical Encoders have much longer history than magnetic ones. There are hundreds of optical encoder manufacturers and the completion has been very keen. Therefore, their cost is reasonably low. The cost of magnetic one is still higher than optical ones because of shorter history and less competition.

However, in the following cases, magnetic encoders can offer features than optical ones.

1) Lower cost in severe environments with the longer life.

2) Survive in very severe environments where Optical ones can not survive even for seconds. With vapor, oil, mechanical shock or vibration, optical one can not survive but magnetic can.

3) Very small encoder like 6mm diameter encoder.

4) Very big encoder to be mounted onto over 200mm diameter motor shaft directly without any coupling.

5) Custom made magnetic encoder can be made from one set at lower cost than optical one since a rotor can be made by machining without a photo-mask like a glass rotor.

7) Air-gap Control Required forMagnetc Encoder

In order for the users to enjoy the features of magnetic encoders, they are requested to control the air-gap between a sensor and a rotor. Air-gap control is necessary to enjoy a long life with bearlingless structure. Users may not like this job but it is much easier than matching a motor shaft and a coupling for optical encoder.

Finally, both magnetic and optical encoders will keep their places depending on applications and

environments. They will coexist sharing the market.

To get the detailed information about Astec JR Magnetic Rotary Encoders,

visit the website of Astec Co., Ltd. at Google.

Contact : <m.ogawa-moc(at)parkcity.ne.jp>

Astec Co., Ltd.