There are three factors that affect the quality and function of the tantalum film: 1) the nature and structure of the material to be deposited (ie, the metal tantalum), 2) the quality and performance of the source material (ie, the tantalum target), and 3) the inherent performance and layout of the deposition system and its associated peripherals.

The nature and structure of the material to be deposited cannot be changed. The only thing you can do is to change another material, such as aluminum, molybdenum, or else.

Tantalum is dense, ductile, very hard, easily fabricated, and highly conductive of heat and electricity, which is a good coating material. So you don't need to worry about its inherent nature will have bad influence on the deposited film. Also, this article does not discuss the first factor but focuses on the latter two factors.

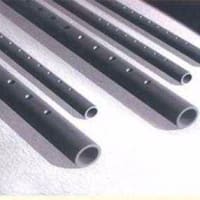

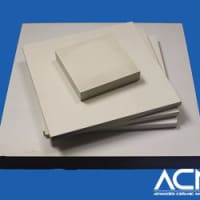

The sputtering industry has high requirements for source materials. The tantalum target used for sputter coating generally has a purity between 2N and 5N. While for special industries, such as the electronics industry, the purity requirement of the tantalum target is generally before 4N-6N.

In addition to purity, density is also an important measure of the target quality. The density of the target material not only affects the sputtering rate, but also affects the electrical and optical properties of the film. In general, the higher the density of the target material, the better the performance of the film. Additionally, increasing the density and strength of the target material allows the target material to better withstand thermal stresses during sputtering.

Another measure of the quality of the deposition source is the grain size. For the same target material, the sputtering rate of the target having a small grain size is faster than the sputtering rate of the target having a large grain size; the thickness distribution of the target sputtering film having a small grain size difference is more uniform. In order to obtain qualified bismuth targets, we recommend purchasing from Stanford Advanced Materials, a global sputtering target supplier.

After talking about the source material, let's take a look at the deposition system. Undoubtedly, if a sputtering system with poor sealing properties, structural disorder, and old equipment is used for coating, even if the source material is good, a satisfactory film cannot be deposited. Therefore, a well-designed, well-equipped sputtering system is essential. It is still recommended that you purchase a sputter machine from a trusted manufacturer and have regular maintenance to ensure that the system is operating properly.

For more information, please visit https://www.sputtertargets.net/sputtering-target.html.

The nature and structure of the material to be deposited cannot be changed. The only thing you can do is to change another material, such as aluminum, molybdenum, or else.

Tantalum is dense, ductile, very hard, easily fabricated, and highly conductive of heat and electricity, which is a good coating material. So you don't need to worry about its inherent nature will have bad influence on the deposited film. Also, this article does not discuss the first factor but focuses on the latter two factors.

The sputtering industry has high requirements for source materials. The tantalum target used for sputter coating generally has a purity between 2N and 5N. While for special industries, such as the electronics industry, the purity requirement of the tantalum target is generally before 4N-6N.

In addition to purity, density is also an important measure of the target quality. The density of the target material not only affects the sputtering rate, but also affects the electrical and optical properties of the film. In general, the higher the density of the target material, the better the performance of the film. Additionally, increasing the density and strength of the target material allows the target material to better withstand thermal stresses during sputtering.

Another measure of the quality of the deposition source is the grain size. For the same target material, the sputtering rate of the target having a small grain size is faster than the sputtering rate of the target having a large grain size; the thickness distribution of the target sputtering film having a small grain size difference is more uniform. In order to obtain qualified bismuth targets, we recommend purchasing from Stanford Advanced Materials, a global sputtering target supplier.

After talking about the source material, let's take a look at the deposition system. Undoubtedly, if a sputtering system with poor sealing properties, structural disorder, and old equipment is used for coating, even if the source material is good, a satisfactory film cannot be deposited. Therefore, a well-designed, well-equipped sputtering system is essential. It is still recommended that you purchase a sputter machine from a trusted manufacturer and have regular maintenance to ensure that the system is operating properly.

For more information, please visit https://www.sputtertargets.net/sputtering-target.html.

※コメント投稿者のブログIDはブログ作成者のみに通知されます