The rising spending power of consumers in developing countries, such as China, India, and Indonesia, is one of the major factors propelling the demand for hot melt adhesives. These nations have undergone robust economic growth over the last few years, which has increased the per capita and disposable income of the people living there. This has, in turn, boosted the demand for various products, in which hot melt adhesives are used, such as footwear, electronics, and clothes. For instance, hot melts are extensively used in electronic products for combining together two substrates.

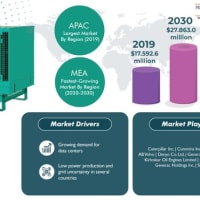

The large-scale industrialization and subsequent growth of the packaging industry across the globe is another key factor responsible for the surge in the demand for hot melt adhesives, especially in the developing nations of Asia-Pacific (APAC), primarily due to the increasing purchasing ability of people and the development of environment-friendly products. Thus, the global hot melt adhesives market is projected to advance at a CAGR of 5.7% during the forecast period (2018–2023) and generate revenue of $10,259.7 million in 2023, compared to $7,353.1 million in 2017.

Get a sample copy of the market report: https://www.psmarketresearch.com/market-analysis/hot-melt-adhesives-market/report-sample

There are numerous types of hot melt adhesives available in the market, namely styrenic block copolymer (SBC), polyamide (PA), metallocene polyolefin (MPO), amorphous polyalphaolefin (APAO), polyurethane (PU), ethylene vinyl acetate (EVA), and polyester. Amongst these, the EVA variants registered the largest sales in 2017, which is mainly attributed to their various advantages such as longer durability, quicker setting time, and suitability at a wider temperature range. Additionally, the rapid advancements in the automotive and construction industries are predicted to further push the demand for the EVA variants in the coming years.

Hot melt adhesives are widely used in various processes pertaining to furniture, textile, automobile, bookbinding, and diaper production. Out of these, the sales of hot melt adhesives are expected to escalate at the highest pace to the automobile sector in the coming years, owing to the rising usage of these adhesives in the assembly of commercial and personal vehicles. The transitioning of automobile manufacturers from conventional methods to new techniques of component assembly is the biggest factor currently shaping the hot melt adhesives market.

The different components of an automobile have been, generally, bonded together by conventional methods, such as by using welds or mechanical fasteners, which provide high strength and efficient performance. However, since the last few years, consumers have started preferring different and more sophisticated vehicle designs, which require the use of hot melt adhesives during the assembling process. This, apart from the rising popularity of low-weight automobiles, is causing the shift toward new bonding techniques. The latter is the results of the focus on higher fuel economy, as lower weight equals lesser burden on the engine.

Globally, the highest demand for hot melt adhesives was witnessed in Europe in 2017. This is mainly attributed to the higher spending power of Europeans as compared to the people in most other regions. Moreover, the presence of major automobile manufacturing companies directly contributes to the huge demand for hot melt adhesives in the region. APAC, on account of the burgeoning need for high-performance materials in various industries, such as automobile and electronics, is expected to register the fastest growth in demand for hot melt adhesives during the forecast period.

Hence, the escalating need for strong yet low-weight binding materials for a wide range of industrial applications will substantially raise the demand for hot melt adhesives in the coming years.

The large-scale industrialization and subsequent growth of the packaging industry across the globe is another key factor responsible for the surge in the demand for hot melt adhesives, especially in the developing nations of Asia-Pacific (APAC), primarily due to the increasing purchasing ability of people and the development of environment-friendly products. Thus, the global hot melt adhesives market is projected to advance at a CAGR of 5.7% during the forecast period (2018–2023) and generate revenue of $10,259.7 million in 2023, compared to $7,353.1 million in 2017.

Get a sample copy of the market report: https://www.psmarketresearch.com/market-analysis/hot-melt-adhesives-market/report-sample

There are numerous types of hot melt adhesives available in the market, namely styrenic block copolymer (SBC), polyamide (PA), metallocene polyolefin (MPO), amorphous polyalphaolefin (APAO), polyurethane (PU), ethylene vinyl acetate (EVA), and polyester. Amongst these, the EVA variants registered the largest sales in 2017, which is mainly attributed to their various advantages such as longer durability, quicker setting time, and suitability at a wider temperature range. Additionally, the rapid advancements in the automotive and construction industries are predicted to further push the demand for the EVA variants in the coming years.

Hot melt adhesives are widely used in various processes pertaining to furniture, textile, automobile, bookbinding, and diaper production. Out of these, the sales of hot melt adhesives are expected to escalate at the highest pace to the automobile sector in the coming years, owing to the rising usage of these adhesives in the assembly of commercial and personal vehicles. The transitioning of automobile manufacturers from conventional methods to new techniques of component assembly is the biggest factor currently shaping the hot melt adhesives market.

The different components of an automobile have been, generally, bonded together by conventional methods, such as by using welds or mechanical fasteners, which provide high strength and efficient performance. However, since the last few years, consumers have started preferring different and more sophisticated vehicle designs, which require the use of hot melt adhesives during the assembling process. This, apart from the rising popularity of low-weight automobiles, is causing the shift toward new bonding techniques. The latter is the results of the focus on higher fuel economy, as lower weight equals lesser burden on the engine.

Globally, the highest demand for hot melt adhesives was witnessed in Europe in 2017. This is mainly attributed to the higher spending power of Europeans as compared to the people in most other regions. Moreover, the presence of major automobile manufacturing companies directly contributes to the huge demand for hot melt adhesives in the region. APAC, on account of the burgeoning need for high-performance materials in various industries, such as automobile and electronics, is expected to register the fastest growth in demand for hot melt adhesives during the forecast period.

Hence, the escalating need for strong yet low-weight binding materials for a wide range of industrial applications will substantially raise the demand for hot melt adhesives in the coming years.

※コメント投稿者のブログIDはブログ作成者のみに通知されます